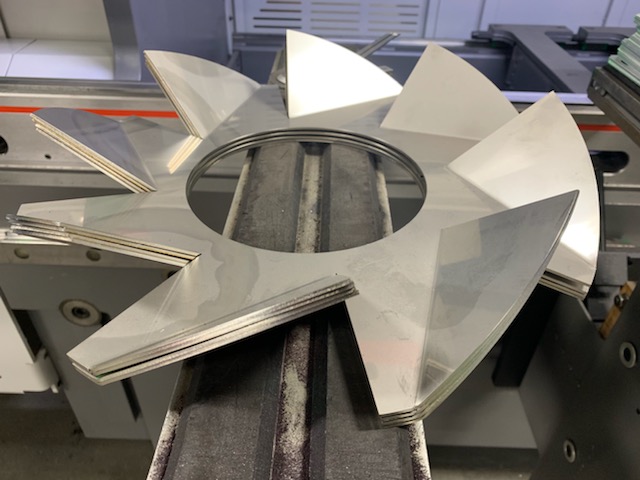

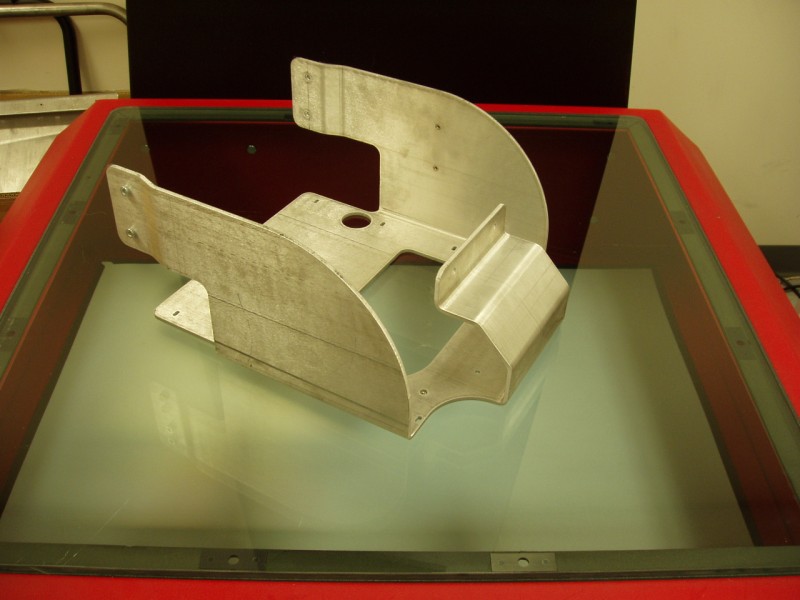

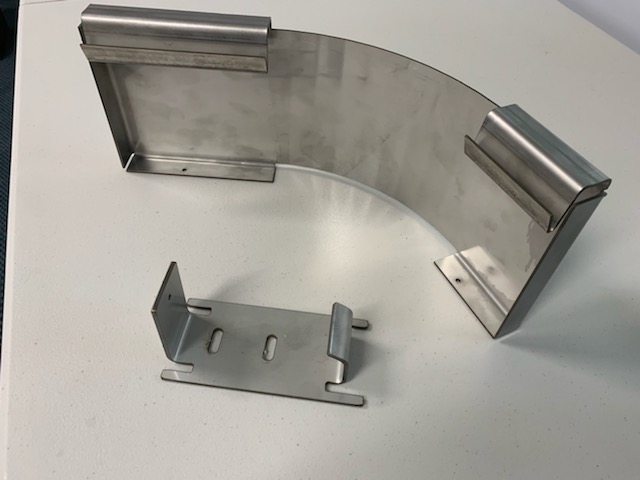

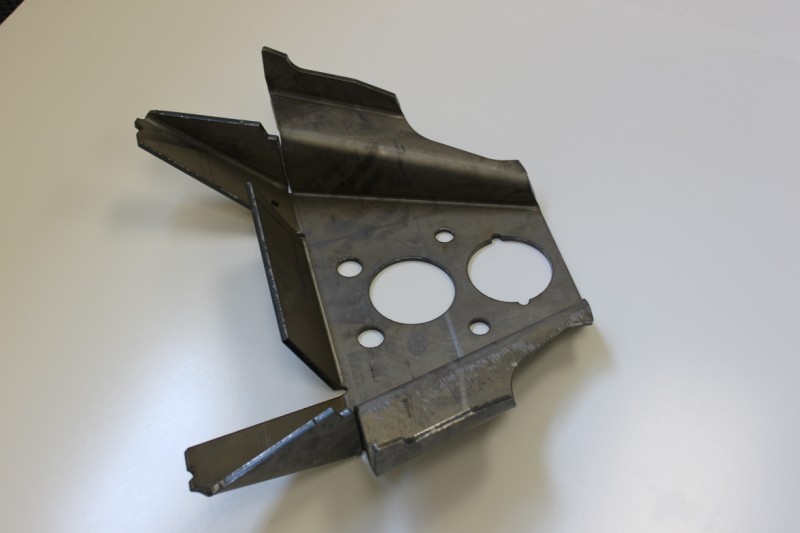

Sheet Metal Forming

Bassett Industries, Inc. uses CNC press brake machines driven by CAD/CAM programming for precision bending and forming of sheet metal parts that meet or beat customer requirements and specifications.

Our CNC press brakes are capable of bending and shaping sheet metal with capacities up to 350 tons, and our systems are equipped with a 9 axis back gauge to ensure repeatable positions.

Touch screen programmable CNC controls in our metal forming systems with unlimited offline capabilty program. With the help of our comprehensive set of in-house dies, including radius dies and hemming dies, we offer quick turnaround and short lead times for our CNC bent and formed parts.

Specifications

Materials Used |

|

Bending Length |

4,100 mm 161.42″ |

Maximum Tonnage |

320 metric tons 353 short tons |

Types of Fabricating |

Welding (MIG, TIG, Spot) Laser Cutting Roll Bending Saw Cutting Swaging Flaring |

Production Runs |

From prototyping to high volume production |

Designing Assistance |

Sheet Metal Forming: Use the same ISR for all bends unless required |

Quality Process and Certifications |

|

Preferred Drawing File Formats |

SolidWorks Files, Part, Assembly, Drawing, DXF, DWG, Adobe Photoshop Files, Adobe Illustrator Files, Template, Parasolid, IGES, STEP AP203/214, ACIS, VDAFS, VRML, STL, Catia Graphics, ProE Part, ProE Assembly, UGII, Inventor Part, Inventor Assembly, Solid Edge Part, Solid Edge Assembly, CADKEY, IDF, Rhino Files |

Secondary Services |

|

Industries Served |

At Bassett, we take on all jobs that fit our capabilities, for any industry. Below are examples of industries we have served in the past. We have created true turnkey components, weldments and assemblies for, but not limited to the following industries:

Agricultural, Alternative Energy, Appliance, Automotive, Computers, Construction, Defense, Distribution, Electronic, Fabrication, Furniture, Hardware, Health and Fitness, Heating and AC, Heavy Equipment, Lawn and Garden, Material Handling, Petroleum and Mining, Race Car & Stock Car, Refrigeration, Retail & Display, Solar Energy, Wind Energy |